Puffing-snack production line mainly uses potato starch, corn starch, tapioca starch and corn flour as raw materials. After being extruded and ripened by a screw extruder, it is cut into semi-finished products of various shapes. Through the transformation of different molds, we can produce shell, spiral, tube, sheet, strip and other three-dimensional and novel shape products, and then fried flavor crisp, suitable for all ages, deeply loved by consumers.

All kinds of puffed snacks

As for the traditional processing method of grain food, it generally needs to go through crushing, mixing, molding, baking or frying and other production processes. Each process needs to be equipped with corresponding equipment. The production line is long, covers a large area, the process is complicated and the labor intensity is large. When processing grain food with extruding and puffing snack machine, the raw materials need only to be initially crushed and mixed, then cooking, enzyme inactivation, sterilization, forming, pre-drying and other processes can be completed on a extruder. Therefore, the process is greatly simplified, energy consumption is reduced, and the whole production process has almost no loss, the manufacturing cost is significantly reduced and pollution-free. Therefore, extrusion technology is a new food processing technology with multi-function, high yield and high quality.

Puffed food production line

Characteristics of extruding and puffing of snack making machine:

1.Improve food quality and easy to store

The mechanical bulking technology made of snacks can make the coarse and hard tissue structure of corn and sorghum, which originally contains more cellulose and vitamins, become fluffy and soft, and the maillard reaction generated in the bulking process increases the color, aroma and taste of food. Thus improve the practical quality, so that the food has an unique flavor that body light, crisp and rich fragrance.

Puffed snacks with good color, aroma and taste

2.Improve product quality and reduce harmful substances

The extrusion process of the snack making machine is a typical high temperature, high pressure, short time process, which makes the material processing limited, so almost all the nutrients in the raw material are retained in the final product. At the same time, high temperature short – term processes still reduce undesirable product factors such as harmful enzymes and microorganisms.

3.Snack making machine raw materials wide applicability, product variety

Snack making device can be processed with a wide variety of raw materials, not only grain, potato, beans and other food for deep processing, so that coarse grain become fine, and produce exquisite snack food; It can also process fruits, vegetables, spices and some animal protein. When the snack maker produces puffed snacks, it only needs to change the raw materials and mold head to produce products of different shapes.

All kinds of mould

4.The snack making machine has high production efficiency and low production cost

The production capacity of large twin screw extruder reaches tens of tons per hour, and the operation is simple. Compared with the traditional cooking method, the processing of products with snack extruding and expanding machine has a significant reduction in time consumption, energy consumption, labor force and factory occupancy.

Technological process of the new multi-functional food puffing machine and complete equipment for puffing food:

Material configuration — mixing — extruding — shaping — cutting — drying — seasoning — (packaging)

Mix process

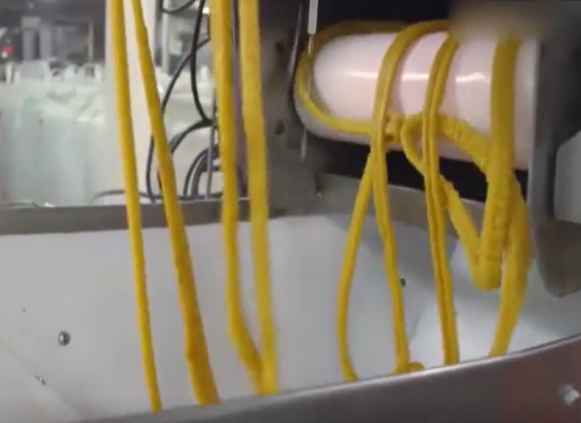

Extrusion processing

Puffing

Drying Seasoning

One purpose of food processing is to make full use of existing food resources, to open up new sources of raw materials, and to develop a wide variety of popular foods. The appearance of puffing technology can be said to open up a new way for the application of raw materials such as grain and starch in food industry. In addition, puffed food generally needs to be processed with flavoring, so the development of puffed food processing industry will certainly drive the development of the flavoring industry, and at the same time promote the development of packaging technology such as film.