Fish is a very common creature in our life. There are many kinds of fish, including ornamental fish and fish specially used for eating. Fish need fish feed in the process of feeding. The quality of fish feed will directly determine the growth of fish. We are a professional manufacturer of fish feed extruders, the production of equipment for many customers to bring convenience.

Recently, a customer from Canada contacted us, saying that they need to order 3 fish feed extruders. After various comparisons, they believe that we have great advantages. They want to decide whether to have a long-term cooperation with us after field investigation. We received them very warmly and introduced them to all aspects of our equipment.

Visit of Canadian clients

Advantages of fish feed extruder:

- High speed, high performance and stable extrusion

Fish feed extrusion machine has a very strong practicality, stable performance, once started, fish feed can be produced at a uniform speed, and the size of the fish feed produced is uniform, with a scientific nutrient ratio, easy to digest after eating, conducive to the growth of fish.

- High production efficiency

Different from the traditional feed production machine, the fish feed extrusion equipment adopts the mechanized operation mode, which is easy for the staff to operate. In the process of operation, the input of manpower can be reduced, which greatly improves the production efficiency and brings more profits to the factory.

- Reasonable energy consumption

Feed extruder in the use of the process only need to consume a small amount of electric energy, can greatly reduce the production costs of manufacturers, making manufacturers further increase the profits.

- Long service life

The service life of the machine will determine the manufacturer’s input cost, the feed extrusion machine is made of high-quality materials, long service life, durable and not easy to wear, a lifetime of use, to help manufacturers reduce production costs.

- Low noise, smooth operation

After the start-up, the feed extrusion equipment can achieve low noise and smooth production, which is a very favorable thing for the staff, will make the staff’s working environment has a great improvement, work enthusiasm greatly increased.

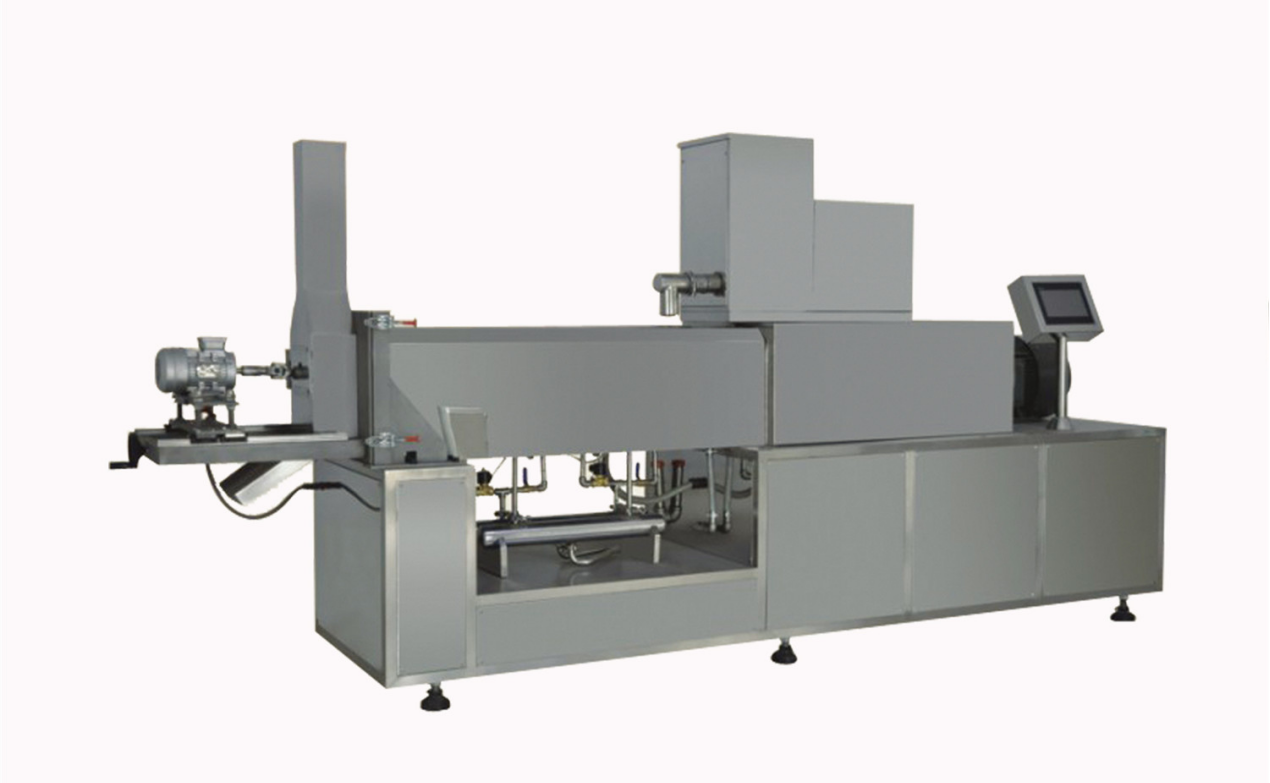

Fish feed extruder

In order to let our Canadian customers have a comprehensive understanding of our fish feed extruder, we introduced several different types of equipment for them, so that they can choose and buy according to their actual production needs, they appreciate our carefulness.

Technical parameters of fish feed extruder:

| Power | 30KW | 60KW | 90KW |

| Processing capacity | 0.1-1t/h | 1-3t/h | 3-6t/h |

| Applicable animal type | Poultry, aquatic products, livestock, pets, fish | ||

| Automatic | Fully automatic production line | ||

| Artificial | 1-2 workers | ||

| Installation | Free installation and debugging training | ||

| Material | Food grade stainless steel | ||

| Processing customized | Yes | ||

fish feed

Finally, the Canadian customer chose the most suitable fish feed extruder for them. After a long talk, both of us were very satisfied with the meeting. The Canadian customer also decided to have a long-term cooperation with us in the future. Customers will further purchase our pet food machine, sandwich snack machine and other equipment, they said they expect us to bring them greater surprise.We are also very happy to make friends from Canada, so we give them some discount, at the same time we will also provide our best after-sales service.

As a leading manufacturer of fish feed extrusion mechanism in the industry, our equipment has been well received by customers from many countries and regions around the world. We will continue to work hard to provide customers with better quality equipment!